Manual filling machine, details fat SER 148-Velps

1. Installation

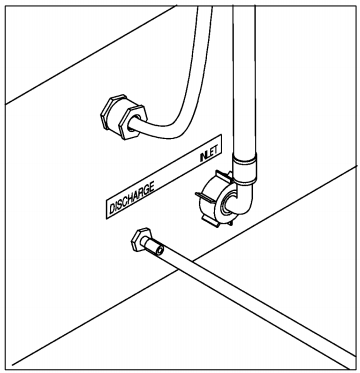

- Connect the machine with water cooling line (INLET) and waste water lines (Dischange) According to the sticker behind the equipment

- INLET – Plastic pipes are fixed by splint. Open water source must have traffic in the output range 3 liters/minute

- DISCHARGE- Cooling water output.

2. Safety standards

All electrical parts must be separated completely with solvent. The machine must be protected too heat with temperature sensor. When the temperature exceeds the maximum allowed 20theC then the air will ngăt.

The following situations can occur:

- Disconnect the temperature sensor circuit. In this condition, the main sensor of temperature exceeded 350the If the safety sensor disconnected the screen show AL2 and the 350.

- Short circuit protection. The temperature of the lower probe 2the For the main probe display AL1 and 000. If the protection were converters short circuit, AL2 and display 000.

- Overheating. In this case,, temperature probes with corresponding setpoint 20the For the main probe, the display of the temperature and AL1 thermal. If overheating, the display will show the temperature of the surface and A thermal.

- Lack of cooling water. A proper design flow check cooling water intake during activity for the discontinuation of solvent vapors in glass mugs. If the main water tap not open at the time of the launch of the new working cycle this cycle will not start, and there is lack of water cooling alarm, the display AL3 and H2O. If in the process of work that lack of cooling water, warning signals lost in a minute after automatic operation cycle interrupted and AL3 shown on screen. To restart, Press the any.

3. Control surfaces

Main breaker: Power supply for air.

The screen 1 (on): The show constantly the temperature of the thermal.

The screen 2 (under): show all settings:

- The program works: P01, P02, …, P29.

- Winning the temperatures for each program

- Operating time of each program (soak, wash, recovery)

The LED: theC set temperature

I: embedded time boiling solvents

In: Discharge time backwards

R: Load times exiled solvents.

- The key SET: Press the SET letter P (by P01) flashes for a few seconds in the display 2, next to select new programs by using the keyboard,↓.

- The key ↵: While the programming used to confirm the value displayed. In the course of the work to confirm the pass to come to another one.

- ↑ Keys: Increase the value in the second screen 2

- The key ↓: Reduce the value in the second screen 2

- The key Start/Stop: Running start or stop programs.

- The key Air: Turn the pump put gas into the average cooling water.

4. Latest programs and launch

- Turn on the main breaker the Indian way. The screen on the display of the temperature of thermal, While the screen below displays the number of the last set program.

Select the program:

- Can set and select 1 in 29 the work program includes: set the temperature, 3 the time for 3 step (Drench, wash, recovery )

- Press the SET, Letter P flashing in the screen below, can then select 1 the new program with ↑ or ↓.

Set program:

Each program includes 4 parameters:

- Working temperature : latest from 30 to 260theC

- Embedded time water : latest from 000 to 999 minutes

- Wash time: latest from 000 to 999 minutes

- The restore time: latest from 000 to 999 minutes.

- Choose the program that works, settings and then press the ↵, lamp theC Turn On and the screen below displays the temperature set, the temperature can be changed from 30 to 260theC press the increase/decrease.

- Confirm the value displayed by pressing ↵ , the lights I am and the show time display embedded water (According to the minutes). This time can be changed from 000 to 999 minutes with ↑ or ↓ key way.

- Confirm the value by pressing ↵ , and repeat the above steps for the time of washing and recovery time. After the confirmation times 3, the display of the program set . If only temperature settings without setting the time, the timing of the process would be 000.

- If in the process of installing programs not key was within 10 seconds, the display will return to show the number of the program.

- While the machine is in the work cycle, then cannot change the parameters.

Launch:

- After installing the program, Press START/STOP to start running. The corresponding lights will light for the active process.

- Lamp theC show the surface thermal is reached the temperature set, While the screen below displays the number of the program being used.

- When the set temperature is reached, the screen below will start showing the embedded time be counting backwards, and I am.

- Ends the process of embedding, the machine will signal newspaper. To start the process wash press ↵, W lights lit and the screen displays the time for washing backward counting

- Ends the process of washing warning sound, Press ↵ to start the recovery process

- The screen displays the countdown time. At the end there will be a warning tone and the screen displays END, at the same time heat will face off

- If the temperature of the heat at the time of starting the new cycle is higher than the temperature set, This cycle will not start, sound and warning screen above show the EEE.

5. Select the temperature heats

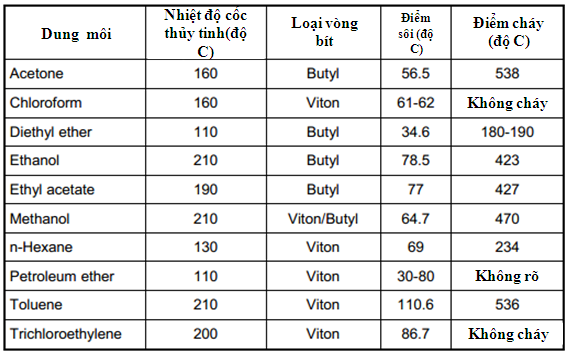

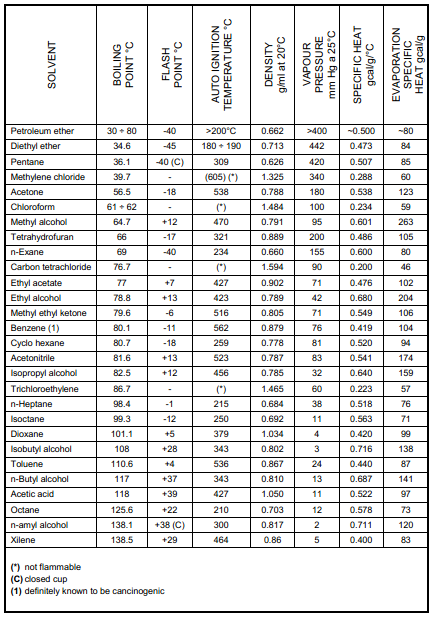

- The temperature of the heating surface is selected in the relationship to the solvent used

- The difference between the temperature of the surface heat and boiling point of the solvent natural border from 100theC for the boiling point at low temperature (as điethyl ether) to 260theC for the boiling point at higher temperatures.

- This is due to the resistance of heat transfer process of Zhejiang glass vase. It was noted that although the temperature of the surface heat never reach the fire temperature of solvent use.

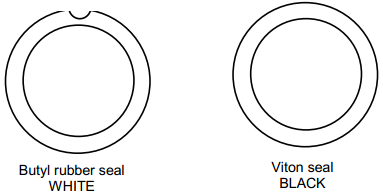

Select rings SEAL

Have 2 as materials

- Viton : Polymeric fluorine

- Butyl Rubber : synthetic rubber

6. Operation

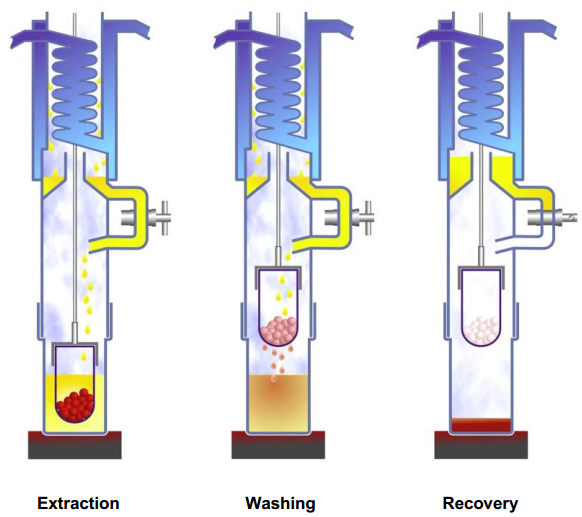

After the installation of new equipment, should use a work cycle the drum with a solvent. The purpose is to remove the traces of lubricating the Assembly which can do wrong results in the first extraction

- Turn on the device

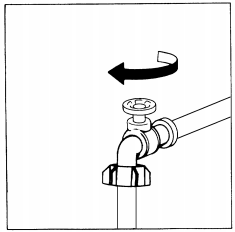

- Opened the water-cooling

- Latest heat temperature in relation to the solvent used. Use stuffing Seal compatible

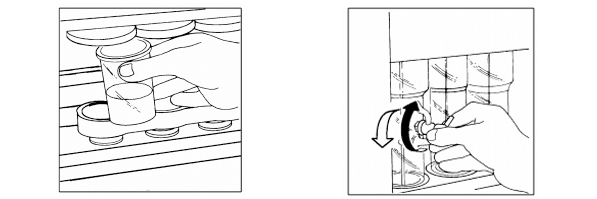

- Put the template into the sleeves if the preliminary hydrolysis is not necessary. Connect to the switch bushings, wear gloves to avoid contamination

- Put the tube lining bundled into the device with front knob in the Immersion position

- If preliminary hydrolysis is done, put into the device with ceramic Cup form has dried hydrolysis, use the Cup provided with ceramic, HU6 (options)

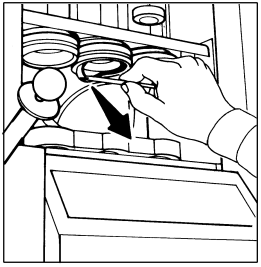

- Put the average discount, preweighed with Chip boiling and filled with solvent into position on the thermal.

- Pull down to fasten the tube filling

- Place the glass valves positioned on the condenser vertical position (Open)

- Start to heat

- Pull the knob slowly gotten about the Immersion position when the solvent start boiling

- At the end of the process of extraction of the solvent is boiled, move the knob of Washing

- At the end of the filling in the boiling solvents, move the knob of Washing

- At the end of the washing, rotate the valve to the glass of horizontal (close) and wait for the extra solvent in the lower part of the glass condenser.

- Drag the need maintain a plethora of back, remove the glass filling tube, remove the sleeves or cups, ceramic. Recover solvent placing empty beakers on the surface heat and open the lock valve.

7. After you finish using

- Closed cooling water

- Power off the device

Always put the empty Cup on the surface heat to avoid dripping

8. Maintenance, maintenance.

a. Wash filter cooling water

- Interrupt source

- Remove the source of the water on in the device

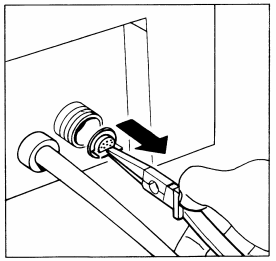

- Use small tweezers pull the filter out

- Wash with water or compressed air

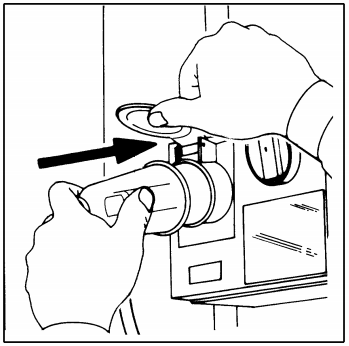

- Location : located between the condenser and the Zhejiang glass pipes

- Replace when using solvents require different rings

- Use a small clamp or tovit to hook and pull out

Contact technical innotec equipment joint stock company Vietnam to be more advice on products by mobile number: 0902.106.379-Mr. Options.

Readers comments (0)