Method of sterilization and disinfection methods are widely applied and much needed in the analysis of experiments : Pharmaceutical products, chemicals, microbiology, health ...

Sterilization , What is sterilization ?

The sterilization to alleviate or destroy bacteria , germs to prevent spread but decent cell for this method has no effect.

Sterilization is to kill all living organisms harmful, including cell Spanish

The method of sterilization of medical instruments are most effective

Choice the method of sterilization would also have to obey the rules and elements of that product to ensure sterile process without any adverse change occurs. Failure to comply with these regulations, will lead to the damage model. Typical programs such as steam sterilization or dry heat sterilization requires the correlation of temperature, the pressure measurement made by the sensors integrated in the autoclaves. Select time and temperature sterilization depends on factors of the nature of the product.

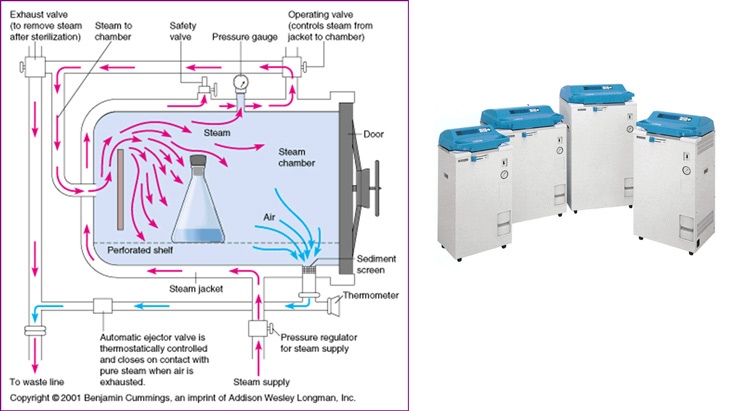

1. His heat in autoclaves (Steam sterilization)

The microorganisms are exposed to saturated steam will make them completely annihilated due to the reverse of the denaturing enzymes and protein structure. Saturated steam sterilization requires precise control of time, temperature and pressure. This method was much application in the sterilization of instruments as well as the How to sterilize medical instruments.

Parameters to agenda during autoclave sterilization is: 121 degrees C within 15 minutes (200kPa). The temperature used to control the process of pressure also to create the steam temperature at the request (the pressure increasing the temperature the greater the)

|

The heat it theC |

About pressure, kPa |

Sterilization time dark urine |

|

126-129 |

250 (~ 2.5 atm) |

10 minutes |

|

134-138 |

300 (~ atm 3.0) |

5 minutes |

Minimal sterilization time is calculated from the time of all the material in the Chamber reaches the required temperature. The monitoring of the physical conditions in autoclave sterilization is very important to ensure the products quality and safety equipment, people.

The solution in glass jars often reach thermal equilibrium within the 10 minutes for the volume of 100 ml and 20 minutes for 1000 ml.

The porous form as: surgical tape ... should be used to ensure the temperature and steam-sterilized entered in the form. Most of the dressings are completely only by process them at a temperature 134-138 degrees C in 5 minutes.

In certain cases, glass, ceramic tile, or metal products are disinfected in 121-124 degrees C within 20 minutes

Fat, the oil can be sterilized in 121 degrees C in 2 now, and if possible should be sterilized using dry heat.

In some cases (for example the: thermolabile compounds) the UHT can stay under 121 C provided that the combination of time and temperature selection has been confirmed. You should find out in advance about the sterilization method for the substance.

2. Dry heat sterilization method

In the dry heat sterilization process is considered the oxidation of cell components. This requires a higher temperature of moist heat and longer exposure time. This method, more convenient for the material does not contain water that cannot be sterilized by steam (due to the harmful effects of water vapor will damage the material) for example the: glass, powder, oil and some oil injection. Can the use of the drying to cleaning and drying equipment 1 the most common way

The preparations are pasteurized by the dry heat is filled in the tank for the device with the parameters given in the table below.

|

Sterilization temperature Max introduction theC |

Sterilization time (minutes) |

|

160 |

180 |

|

170 |

60 |

|

180 |

30 |

View more : chemical laboratory instruments

The specific conditions of time and temperature for sterilization are detailed in the documentation.

Dry heat sterilization equipment equipped with an air circulation system to ensure uniform heat distribution in all the products.

With biological indicators suggested the confirmation of sterilization process is: (. For example: var niger ATCC 9372 or CIP 77,18) spores of Bacillus subtilis that sterilized value dry is 5-10 minutes in 160 ° C use about 106 spores per directive.

3. Filter method

Sterilized by filtration is used primarily for aqueous solutions and non-heat-resistant. They can be sterilized by passing through the filter bacteria sterile barrier, for example: filtration membrane (cellulose derivatives.) plastic, porous ceramics, or glass filters appropriate Binder. The filter contains amiang should not be used because of the harm the environment.

Appropriate measures should be taken to avoid loss of substances by adsorption onto the filter , prevent the spread of pollutants from the filter. Matching filter will prevent the migration of bacteria , microorganisms and go through disinfection solution is then added to the containers immediately to combat bacterial infection back.

Usually, Membrane pore size no larger than 0.22 the microphone should be used. All the filters, the tube and used equipment must be sterilized before. Filters are resistant to heat is sterilized when used in autoclaves 121 It C and in 15-45 minutes depending on the size of the filter.

4.The method of sterilization exposure and ionizing radiation

Antiseptic drug products, laboratory equipment , health in a container or packaging products by exposure to ionizing radiation in the form of gamma radiation from a radioisotope source as appropriate 60 Co (cobalt 60) or the energy of electrons by a suitable electron Accelerator.

Gamma radiation and electrons are used to perform the ionization of molecules in living organisms. So, the mutation formed in this reaction and DNA for replication. The process is very dangerous and trained only with experienced staff.

5. Air sterilization methods

The active agent of the disinfection process by ethylene oxide gas or a very volatile substance. The essence of it is flammable so they are mixed with inert gases to reduce toxicity .

The whole process is very difficult to control so should consider if can not use other sterilization methods. It can only be done under the supervision of skilled workers.

The effect of ethylene oxide sterilization depends on the concentration of the gas, humidity, contact time, the temperature and the nature of the product. Proper sterilization conditions must be determined experimentally for each type.

After autoclaving, the removal of the volatile gases over time, need to confirm this through specific tests.

Above is the top 5 the method of disinfection generator , sterilization and the concept of help you understand more and have more choices for disinfection of medical instruments are also the other utensils !

Readers comments (5)