Drying of Daihan WOC

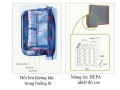

- Drying Daihan WOC improved are the downside of the previous drying model line is specially designed with pressure balancing mechanism of natural convection, the air circulation provides continuous airflow do pollution when discharged from drying is filtered clean right away and then come back to drying to avoid contaminate cross between templates. This is one of the notable advantages of WOC Cabinet line.

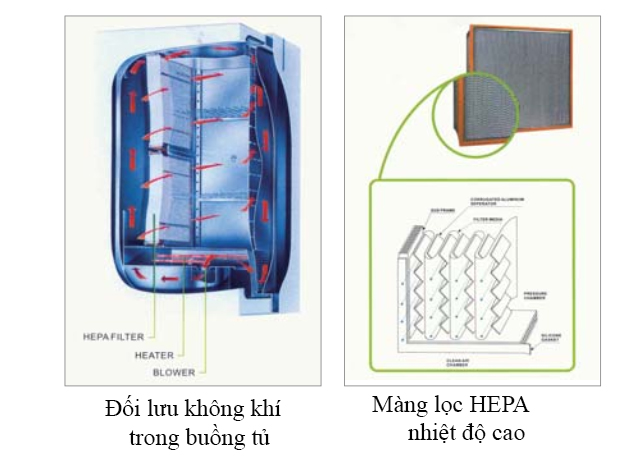

- Drying WOC Daihan suitable for critical applications such as: Electronics, in the laboratory, biotechnology, pharmaceutical and clinical application with HEPA filter 100 for high temperature.

Characteristics of the drying Daihan WOC

- Precise temperature control with digital Fuzzy controllers, allows temperature monitoring during operation of the machine.

- Digital touch screen LCD with Back Light backlight technology.

- The inner structure is made of stainless steel, outside made of galvanised steel corrosion, glass wool fibre insulation should cabinets with high durability, There are aesthetic.

- The door gaskets are made of heat-resistant soft silicon rubber, avoid heat loss.

- Automatic temperature compensation function, controls the difference between the actual temperature and the temperature indicator (± 20ºC)

- Connect to the computer via serial port RS232C

- The archive function: allows to set the value of the temperature and time

- Protect temperature exceeds the allowed, overload protection, sensor fault detection.

- Lock mode supports safety experiments (complete removal of the control button Jog-Shuttle) When drying problems or are in the process of work

There are no reviews yet.