1.Method of equi dynamic isokinetic

a, Isokinetic concept

"iso = same" + "kinetic = movement" (1)

Sample College motivation (isokinetic) is the sampling process so that the speed-at the beginning of sampling (Inn) with the speed of air flow (Ins) in conditions that are not disturbed (Inn= Vs)

]cols]b)The object of the isokinetic method

Use the sampling of substances in the form of particles such as dust, metal powders, dioxin/furan, selling volatile compounds(SVOC)... in the exhaust.

c, Conditions of use of the method of dynamic isokinetic class

The factory chimneys (electric heat, cement, fertilizer, solid waste incinerator.)

- Vortex flow.

- The chimney has a smaller whale 0.3 m.

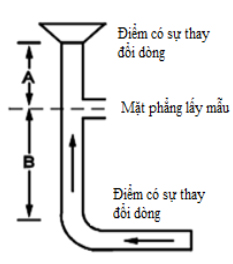

- Does not satisfy the condition: B = 2 * D and the A = 0.5 * D.

*Note: Sampling by dynamical isokinetic class methods (Inn= Vs) the amount of dust collected will equal dust in air flow =>This will increase the accuracy and the reliability of results.

2.Observation of industrial emissions in the field by the method of dynamic isokinetic class.

a,Prepare sample conditions.

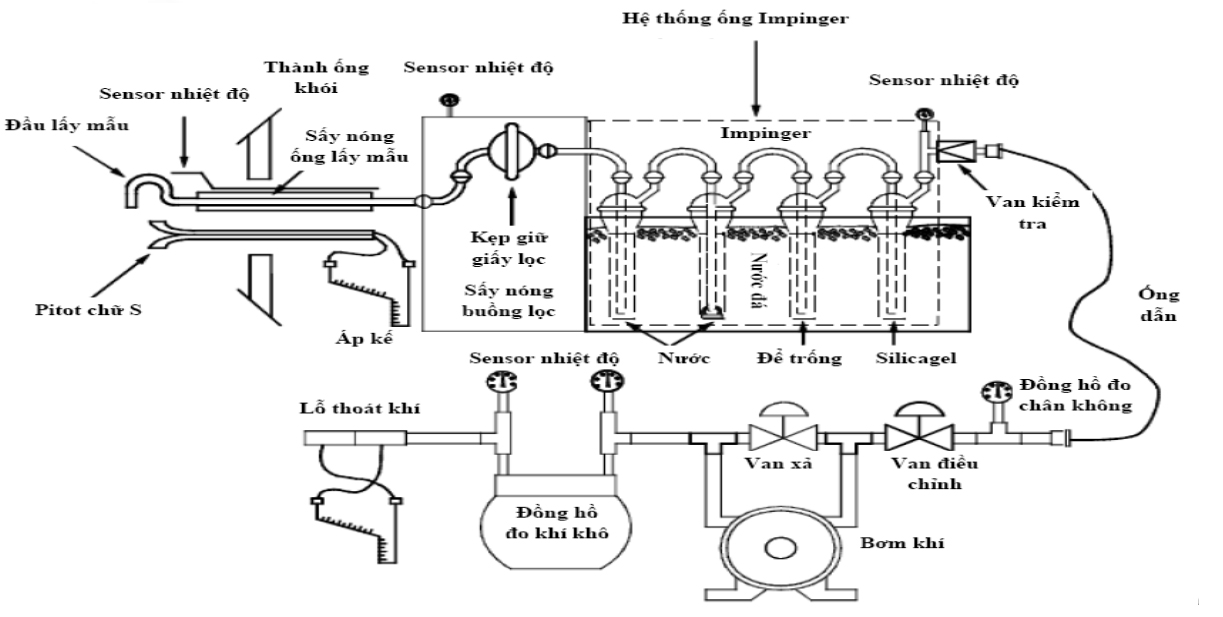

- Isokinetic sampling equipment (combinations of measuring heads, thermal systems , the wet condensate heating system System cable connection, with pump controller)

- S pitot tubes and pressure difference meter according to the EPA2

- Direct measurement of parameters O2 measuring conditions and standard conditions and determine the molar mass of crude gas molecules according to EPA 3) Vietnam cable television, Internet vtvcab

- Electronic scales accurate to 0.1 g(to determine the moisture content of the waste gases by EPA 4)

- The computer (use the calculation program)

- Calculator,slide conversion tool.

- The material, chemicals (the membrane filtration, petri, delicacy , silica gel, distilled water).

Comparison between the methods of air sampling methods 5 method 17

|

Method 5 |

Method 17 |

|

|

The principle of the |

Isokinetic (Inn= Vs) |

Isokinetic (Inn= Vs) |

|

Method |

External flue dust filter, dust filter paper circle => thermal system requirements in 106 – 134 theC => avoid condensation, moisture separator |

Dust filter be put on the inside of the chimney, Paper dust filter cylinder => no need to heat |

|

Pros, the downside |

Using the measured flue has high humidity,easy to form liquid droplets in saturated vapor or |

-The priority used in case the concentration of dust in the large emission. -Do not use the measure funnels have high humidity, easy to form liquid droplets in saturated vapor or. =>Especially some factories use wet methods to treat waste gas before drainage. |

c,Field preparation

*Assembly diagram gas sampling system by dynamical isokinetic class methods

*Note before you start the process of sampling by dynamical isokinetic class methods

- Sampling location and number of points-minimum sample must be determined at the emission source before conducting sampling.

- The need to measure at the scene at the source of emissions is the essential pressure, temperature, the difference in pressure between the pressure and the pressure of the limb (ΔP).

- Humidity was determined according to the method 4 of the US-EPA

- Humidity be translated accurately by the method 4 of the US-EPA

- Choose the file thuớc of pitot tube S ΔP suit aims to maintain the status of the dynamic class sample.

- Rinse wash the parts in contact with the gas line by the solvents acetone before sampling.

*Location of sampling (determined according to the method 1 USEPA's )

- Determine the location of the flow xóay using pressure difference meter.

- Determine maximum speed-, the size of sampling heads.

- Emission source is static pressure , temperature, the pressure difference between the static pressure and dynamic pressure (ΔP).

*Assembly system for measurement and isokinetic ESC include early samples, the membrane filtration, condensing system.

*Check the system

- After you have assembled the equipment according to the diagrams

- Oil S Pitot tube

- Turn on the pump, adjust the pressure meter range-10kpa

- Check the clock save semi-permanent, If the clock stand still, do not move in 10- 20s and moves in the condensation pipe not effervescent sealed system gas gas-sealed system.

- Start of release from the Pitot head

- Turn off the pump and insert the device into the chimney sample preparation.

* Is before and after sampling the need to check the tightness of suction device model

*Operate the sampling equipment

- After determining the location of non-template and mark the location on the need-template by heat resistant pen and melting.

- Moving sampling into the hole placement sample was defined.

- Boot pump, Tuning kite kite Control Panel and proceed recording the chimney temperature information, the air temperature on, gas sampling system out on the table control kite. Notes this parameter sampling system on the control panel. Notes this parameters with frequency from 5 hours/times.

- Each point sampling by dynamical isokinetic class methods, -sample in 5 minutes.

- After the end of a sampling point, sampling tubes to move to the next position and conduct similar lies with the previous sample points.

- Ensuring temperature thermal 120 theC ± 14theC, the output <20theC

- Dust sampling: to learn the number at least 2 Sample/1 gauge.

- Minimum time per sample 1 hours and 1, 5 m3 gas.

*Currency templates

- Use tweezers to transfer the membrane filter into a clean petri has labeled the tape sealed ice petri. paraffin.

- Wash your face in the font S pitot, straws and clutches with multistage tables for the dust filter, Rinse wash 3 times with acetone( to sample the dust sticking inside the tube).

*Method of calculation

Filter paper was drying in 104theC in the 2-3 now, to in the average least hygroscopic 6 now and then the weight to a semi-permanent block does not change (results between weight not exceeding 0.1 mg).

- Acetone washing equipment to natural evaporation to dryness, then weigh to constant weight => determine the weight of sample.

=> The total weight of the samples on filter paper and wash the acetone.

*Calculation and processing of measured data

Units of measure: When the unit conversion from ppm to mg/m3 need to note the kite event of standard gas.

- The school combines standard conditions is 25theC, 760 mmHg

- The school combines standard conditions is 0theC, 760 mmHg

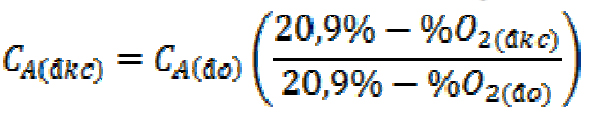

The results was determined by the concentration of oxygen reference

*The QA/QC activities in sample

- The device must be calibrated every year according to circular 23/TT-BKHCN on 2013/ 26 month 9 in 2013 the Minister of science and technology rules of measurement for measuring media group 2;

- Percentage of sampled dynamic class (I) to put in about 90% of the< I <110%.

- Collect white form field tool.

* Things to note before sampling.

- Before conducting the measurement method of dynamic isokinetic class

- Must have a monitoring plan (for each specific effluents)

- Calibration: ensure reliability

- The equipment: Clean toilet, full, have a backup device.

- In collaboration with the plant (Enterprise) to select the sample avatar telescopic, transportation equipment, the operations floor, the power source.

- In the process due to

- Sample event elects to guarantee when the facility operates in conditions representative for

- Longer sampling (TB is 01 now)

- Get repeat 02 visit (the other countries 03 visit )

- After due

- QA/QC

- Uniform don due about kite events (25theC, 760 mmHg and a dry gas)

- Data processing, check the spread of the data.

- Report

Detailed reference download: Method of equi dynamic isokinetic

Readers comments (0)